What Is Sublimation?

Sublimation offers full-color printing capabilities at an affordable start-up cost. All you need to being is a sublimation printer, sublimation inks, sublimation paper, and a heat press. The technology is well-developed, and there is a vast support network of suppliers and users to help when questions arise. Sublimation is also easily scalable. You can start with a small format desktop sublimation printer and expand later to a large format printer for more demanding projects.

Sublimation uses CMYK printing, giving you the ability to reproduce high-quality graphics and photographs. There are thousands of blank sublimation items available, including drinkware, apparel, photo-receptive, and exterior signage panels. The process of sublimation fuses the printed graphic to the blank item, making the finished transfer very durable and able to withstand hundreds (in some cases thousands) of washes without fading.

ADDING SUBLIMATION TO YOUR BUSINESS MEANS ADDING PROFITS!

Once you have decided to get started, in a matter of hours you can be offering your customers

full-color, personalized signs, gifts and more! Plus, adding sublimation to your business is a

great way to attract new customers and grow your product offering. We’ll make sure you get

the right equipment and the right products to attract and retain your customers.

All you need to provide is a computer. Let Johnson Plastics Plus provide the rest. We offer

small and large format sublimation printers, heat presses, ink, paper, and sublimatable

substrates.

THE SCIENCE OF SUBLIMATION

You may have learned in the school that “sublimation” involves a substance that changes from a solid to a gas without ever becoming liquid. In the signage, awards, and personalization industries, it’s the process where images are printed on specialty coated paper, then transferred to a coated surface or substrate.

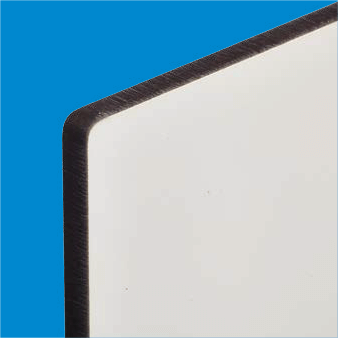

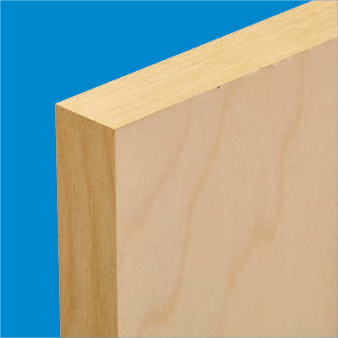

Unlike conventional inks, sublimation inks are converted directly from a solid to gas under heat and pressure, and upon cooling permanently bond with the fibers in polyester. It's this bond that makes sublimation such a durable personalization process. Those fibers could be the polyester in traditional fabrics and other soft goods, but also polyester fibers in the specialized coating applied to sublimatable hard goods such as mugs, tumblers, home decor items, hard board, picture frames, and more. In order for an item to work with sublimation, it has to have polyester in the material itself or in the coating or film.

Long story short, if a product isn't manufactured specifically for sublimation with a polyester coating, it won't work with the process. Thankfully, there are thousands of polyester-coated products specifically for sublimation available from Johnson Plastics Plus. You can be sure that products marked as sublimation-friendly offered through jpplus.com have been thoroughly tested and are ready to be personalized with sublimation.

How do I add sublimation to my business?

Adding sublimation to your business is not only easy but also brings numerous advantages. It's one of the most economical start-ups you will ever undertake, offering high-profit margins as the materials required are relatively inexpensive. Furthermore, it allows for the creation of vibrant, high-resolution transfer that are resistant to fading and wear over time, which means your products will maintain a fresh and new appearance even after prolonged use. It's a fast, low-cost way for you to expand your business into customized full-color gifts and signage. Sublimation is versatile, enabling you to personalize a wide array of items, from clothing to homeware, thus meeting various customer preferences and needs. With a sublimation printer, paper, and heat press, you can offer thousands of new, high-quality, and durable products to your customers in no time, enhancing customer satisfaction and potentially boosting your business reputation and reach.

What does sublimation mean in printing?

In the context of printing, sublimation refers to a process where heat-sensitive inks are transferred from specially coated paper onto materials such as fabrics, ceramics, or metals. The heat and pressure applied during this process causes the inks to transition directly from a solid to a gas state, bypassing the liquid stage. This causes the inks to penetrate the surface of the material, resulting in a high-resolution, vibrant, and durable print.

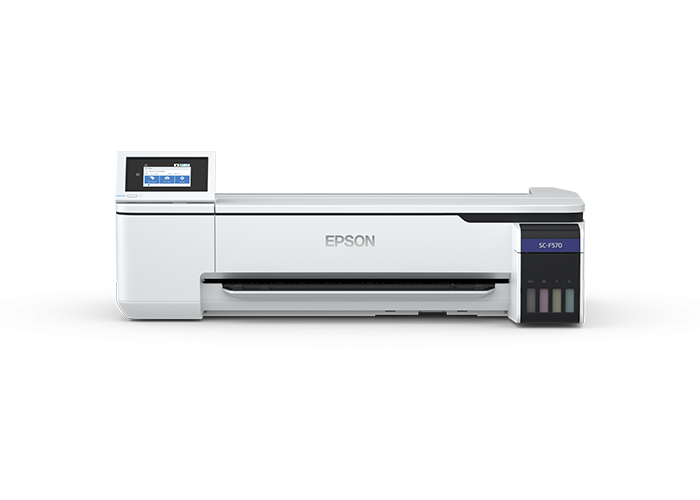

What kind of printer do you need for sublimation?

For sublimation printing, you would require a dedicated sublimation printer equipped with sublimation inks. These printers are designed to handle the specific type of dye-sublimation transfer paper required for the process. Popular brands offering these printers include Epson and Sawgrass. (hyperlink Epson and Sawgrass to respective pages)

Is sublimation better than vinyl?

Whether sublimation is better than vinyl depends on the specific needs of your business. Sublimation offers vibrant, high-resolution prints that are durable and resistant to fading. It works best on light-colored, polyester-based materials. On the other hand, vinyl is versatile and can be applied to various surfaces, including dark fabrics and cotton. However, it might not offer the same level of detail and vibrancy as sublimation. The choice depends on your product range and customer preferences.

Do you need a heat press for sublimation?

Yes, a heat press is essential for sublimation printing. The heat press applies the necessary heat and pressure to transfer the design from the sublimation paper onto the chosen material, facilitating the ink's transition from a solid to a gas state and ensuring a high-quality transfer.

Is infusible ink the same as sublimation?

Infusible ink works on a principle similar to sublimation, where the ink becomes a part of the material instead of simply sitting on top of it. However, infusible ink is often available in the form of pens or markers, allowing for direct drawing or writing onto the transfer paper, which can then be transferred onto the substrate using heat.

What lasts longer, sublimation or heat transfer?

Generally, sublimation tends to last longer than traditional heat transfers. Since the ink becomes part of the material during sublimation, it is more resistant to fading, cracking, or peeling over time. This gives sublimated products a more durable and long-lasting finish compared to heat transfers.

What do you need to do sublimation?

To start with sublimation, you would need the following:

Having a design software to create or edit designs would also be beneficial.